- « Return to page

- Home

- Log In

- Courses

- CITB Accredited Training Courses

- CITB SMSTS - Site Management Safety Training Scheme

- CITB SMSTS-R - Site Management Safety Training Scheme Refresher

- CITB SMSTS Day Release - Site Management Safety Training Scheme

- CITB TWCTC - Temporary Works Co-Ordinator Training Course

- CITB TWSTC - Temporary Works Supervisor Training Course

- CITB SSSTS - Site Supervisor Safety Training Scheme

- CITB SSSTS-R - Site Supervisor Safety Training Scheme Refresher

- CITB HSA - Health & Safety Awareness Course

- CITB SEATS - Site Environmental Awareness Training Scheme

- CITB Directors Role in Health & Safety

- City & Guilds Confined Space Training Courses

- EUSR SHEA Passport and National Water Hygiene Training Courses

- EUSR National Water Hygiene (NWH) (Blue Card)

- EUSR National Water Hygiene (eLearning) (NWH) (Blue Card)

- EUSR SHEA Water

- EUSR SHEA Water Renewal

- EUSR SHEA Water Conversion

- EUSR SHEA Cross Country Pipelines

- EUSR SHEA Cross Country Pipelines Conversion

- EUSR SHEA Gas

- EUSR SHEA Gas Renewal

- EUSR SHEA Gas Conversion

- EUSR SHEA Power

- EUSR SHEA Power Renewal

- EUSR SHEA Power Conversion

- EUSR SHEA Telecoms

- EUSR SHEA Telecoms Conversion

- EUSR SHEA Core

- EUSR SHEA Drains & Sewers

- EUSR SHEA Waste

- Health and Safety Training Courses

- NUCO Emergency First Aid at Work (EFAW) - FAA Level 3 (1 Day Accredited)

- NUCO First Aid at Work (FAW) - FAA Level 3 (3 Day Accredited)

- NUCO Manual Handling Course (Principles and Practice) - FAA Level 2 (1 Day Accredited)

- NUCO Fire Safety Awareness - FAA Level 1 (1/2 Day Accredited)

- NUCO Fire Safety Training - FAA Level 2 (1 Day Accredited)

- NUCO Emergency Paediatric First Aid - FAA Level 3 (1 Day Accredited)

- NUCO Paediatric First Aid, units 1 & 2 - FAA Level 3 (2 Day Accredited)

- NUCO Food Safety in Catering - FAA Level 2 (1 Day Accredited)

- City & Guilds 6318-03 Level 3 Certificate in learning and development

- Technical / Bespoke Training Courses

- EUSR Impressed Voltage Awareness

- EUSR Impressed Voltage for Designers & National Grid Supplier Requirements (SR/234) Overview Training

- EUSR Impressed Voltage for Managers & National Grid Supplier Requirements (SR/234) Overview

- EUSR Impressed Voltage for Managers & National Grid Supplier Requirements (SR/234) Overview & IVDE (ECP/EAP) Training

- Insulated working under impressed voltage conditions (NSI5 equivalent for contractors)

- National Grid CDAE/PD Supplier Requirements SR/106, SR/107, SR/135, SR/141, SR/162, SR/163, SR/175, SR/183, SR/188, SR/193, SR/212 & SR/215 Awareness Training

- National Grid PCSM Supplier Requirements SR/106, SR/107, SR/135, SR/141, SR/163, SR/183, SR/188, SR/234 & SR/241 Awareness Training

- Pre-Competent Person Training

- Requirements of The Electricity, Safety, Quality and Continuity Regulations (ESQCR) 2002

- Substation Appreciation

- CDM 2015 Awareness & National Grid Supplier Requirements (SR/163) Overview Training

- Utility & Construction Training Courses

- BESC AME Overhead Lines

- BESC AME Substation

- EUSR Category 1 - Locate Utility Services & HSG47 Radio Detection (CAT & Genny)

- EUSR Category 2 - Implement Safe (Digging) Excavating Practices

- EUSR Category 3, 4 & 5 - Install, Inspect & Remove Timber, Steel and Proprietary Shoring Systems

- EUSR Category 3, 4 & 5 Refresher - Install, Inspect & Remove Timber, Steel and Proprietary Shoring Systems

- EUSR Approved Abrasive Wheels - Mounting and Practical Use of Equipment

- EUSR Approved Manual Handling

- EUSR Endorsed Butt Fusion Welding

- EUSR Endorsed Electrofusion Welding

- EUSR HSG47 - Avoiding Dangers Underground Services - HV Substations

- EUSR Safe Control of Mains Connection (SCMC) Water Course

- EUSR Endorsed Gas Detection and Personal Gas Monitor Training

- EUSR Endorsed Fire Warden

- EUSR Approved Asbestos Awareness

- EUSR Approved Control of Substances Hazardous to Health (COSHH) Awareness

- EUSR Endorsed Cable Winch - Trailer 3T Capstan Winch

- EUSR Endorsed Cable Winch and Cable Pulling

- EUSR Endorsed Chlorination, De-Chlorination, Flushing & Sampling

- EUSR Endorsed Excavation Management

- EUSR Endorsed Hand Arm Vibration Syndrome (HAVS) Awareness

- EUSR Endorsed Working at Height and Harness Awareness

- Overhead Line Appreciation

- Qualitative Face Fit Testing

- Quantitative Face Fit Testing

- Electrical Training Courses

- City & Guilds 2377-77 In-service Inspection and Testing of Electrical Equipment (PAT Testing)

- City & Guilds 2377-77 In-service Inspection and Testing of Electrical Equipment 3 Day course (PAT Testing)

- City & Guilds 2382-22 18th Edition Full Course (3 days)

- City & Guilds 2382-22 18th Edition BS7671:2018+A2:2022 (1 Day Update including Exam)

- City & Guilds 18th Edition Exam Only

- Thames Water Passport

- Safe Control of Operations (SCO) Gas Training Courses

- EUSR SCO (Safe Control of Operations) Modules 1, 2 & 5: Core, Permit to Work and Form of Authority (Was previously SCO 1&2)

- EUSR SCO (Safe Control of Operations) Modules 1 & 2: Core & Permit to Work (Was previously SCO1)

- EUSR SCO (Safe Control of Operations) Module 3: Non-Routine Operations (NRO) (Was previously SCO4)

- EUSR SCO (Safe Control of Operations) Module 4: Routine Operations (RO) (Was previously SCO5)

- EUSR SCO (Safe Control of Operations) Modules 1, 2 & 5: SCO Core, Permit To Work and Form Of Authority (Previously known as SCO 1&2) Renewal

- EUSR SCO (Safe Control of Operations) Modules 1, 2, 4 & 5: SCO Core, Permit To Work, Routine Operations and Form Of Authority Renewal

- EUSR SCO (Safe Control of Operations) Modules 1, 2, 3, 4 & 5: SCO Core, Permit To Work, Non Routine Operations, Routine Operations and Form Of Authority (Previously known as SCO 1&2, 4 and 5) Renewal

- EUSR SCO (Safe Control of Operations) Module 5: Form of Authority (Was previously part of SCO1&2)

- EUSR SCO (Safe Control of Operations) Module 3: Non-Routine Operations (NRO) (Was previously SCO4) Renewal

- EUSR SCO (Safe Control of Operations) Module 4: Routine Operations (RO) (Was previously SCO5) Renewal

- Network Construction Operations (NCO) Gas / Water Training Courses

- CABWI Level 1 Certificate in Network Construction Operations - NCO1 Water Assistant

- CABWI Level 2 Certificate in Network Construction Operations - NCO2 Water Service Layer

- CABWI Level 2 Certificate in Network Construction Operations - NCO2 Water Main Layer

- CABWI Level 2 Certificate in Network Construction Operations - NCO2 Water Conversion Main and Service Layer

- City & Guilds Level 1 Certificate in Network Construction Operations - NCO1 GAS Assistant

- City & Guilds Level 2 Diploma in Network Construction Operations - NCO2 GAS Service Layer

- City & Guilds Level 2 Diploma in Network Construction Operations - NCO2 GAS Main Layer

- City & Guilds Level 2 Diploma in Network Construction Operations - NCO2 GAS Conversion Main and Service Layer

- EUSR NCO Water Registration

- EUSR NCO Water re-registration

- EUSR NCO Gas Registration

- EUSR NCO Gas re-registration

- National Grid Training Courses

- NG NSI9 Testing High Voltage Equipment

- NG Competent Person Overhead Lines (OHL) CPA LAC ONLY Non-Application of Drain Earths e.g., Civil Works

- NG Competent Person Overhead Lines (OHL) CPB LAC & PFW Non-Application of Drain Earths e.g., Fountain Forestry

- NG Competent Person Overhead Lines (OHL) CPC LAC & PFW Application of Drain Earths (No Access onto Conductors) e.g., Tower Painters who Earth

- NG Competent Person Overhead Lines (OHL) CPD LAC & PFW Application of Drain Earths (Work on Conductors)

- NG Competent Person Substations NSI6 and NSI8 Full

- NG NSI2 Limited Renewal

- NG NSI2 Limited inc Practical Application of Drain Earths

- NG Person Overhead Lines (OHL)

- NG Person Overhead Lines Online Renewal

- NG Person Substations

- NG Person Substations Online Renewal

- NG Restoration of Motive Power (ROMP)

- Streetworks / NRSWA Training Courses

- NRSWA Signing Lighting and Guarding (Operatives)

- NRSWA Signing, Lighting and Guarding (Supervisor)

- NRSWA Signing Lighting and Guarding Reassessment

- NRSWA Operatives Reassessment Course

- NRSWA Supervisors Reassessment Course

- NRSWA Location and Avoidance of Underground Apparatus (LA Old Unit 1)

- NRSWA Location and Avoidance of Underground Apparatus (LA) Reassessment

- CITB Accredited Training Courses

- About us

- Policies

- News & Articles

- Contact

Email: support@pragmatic-consulting.co.uk

Tel: 01926 674340

- Home

- Courses

- CITB Accredited Training Courses

- CITB SMSTS - Site Management Safety Training Scheme

- CITB SMSTS-R - Site Management Safety Training Scheme Refresher

- CITB SMSTS Day Release - Site Management Safety Training Scheme

- CITB TWCTC - Temporary Works Co-Ordinator Training Course

- CITB TWSTC - Temporary Works Supervisor Training Course

- CITB SSSTS - Site Supervisor Safety Training Scheme

- CITB SSSTS-R - Site Supervisor Safety Training Scheme Refresher

- CITB HSA - Health & Safety Awareness Course

- CITB SEATS - Site Environmental Awareness Training Scheme

- CITB Directors Role in Health & Safety

- City & Guilds Confined Space Training Courses

- EUSR SHEA Passport and National Water Hygiene Training Courses

- EUSR National Water Hygiene (NWH) (Blue Card)

- EUSR National Water Hygiene (eLearning) (NWH) (Blue Card)

- EUSR SHEA Water

- EUSR SHEA Water Renewal

- EUSR SHEA Water Conversion

- EUSR SHEA Cross Country Pipelines

- EUSR SHEA Cross Country Pipelines Conversion

- EUSR SHEA Gas

- EUSR SHEA Gas Renewal

- EUSR SHEA Gas Conversion

- EUSR SHEA Power

- EUSR SHEA Power Renewal

- EUSR SHEA Power Conversion

- EUSR SHEA Telecoms

- EUSR SHEA Telecoms Conversion

- EUSR SHEA Core

- EUSR SHEA Drains & Sewers

- EUSR SHEA Waste

- Health and Safety Training Courses

- NUCO Emergency First Aid at Work (EFAW) - FAA Level 3 (1 Day Accredited)

- NUCO First Aid at Work (FAW) - FAA Level 3 (3 Day Accredited)

- NUCO Manual Handling Course (Principles and Practice) - FAA Level 2 (1 Day Accredited)

- NUCO Fire Safety Awareness - FAA Level 1 (1/2 Day Accredited)

- NUCO Fire Safety Training - FAA Level 2 (1 Day Accredited)

- NUCO Emergency Paediatric First Aid - FAA Level 3 (1 Day Accredited)

- NUCO Paediatric First Aid, units 1 & 2 - FAA Level 3 (2 Day Accredited)

- NUCO Food Safety in Catering - FAA Level 2 (1 Day Accredited)

- City & Guilds 6318-03 Level 3 Certificate in learning and development

- Technical / Bespoke Training Courses

- EUSR Impressed Voltage Awareness

- EUSR Impressed Voltage for Designers & National Grid Supplier Requirements (SR/234) Overview Training

- EUSR Impressed Voltage for Managers & National Grid Supplier Requirements (SR/234) Overview

- EUSR Impressed Voltage for Managers & National Grid Supplier Requirements (SR/234) Overview & IVDE (ECP/EAP) Training

- Insulated working under impressed voltage conditions (NSI5 equivalent for contractors)

- National Grid CDAE/PD Supplier Requirements SR/106, SR/107, SR/135, SR/141, SR/162, SR/163, SR/175, SR/183, SR/188, SR/193, SR/212 & SR/215 Awareness Training

- National Grid PCSM Supplier Requirements SR/106, SR/107, SR/135, SR/141, SR/163, SR/183, SR/188, SR/234 & SR/241 Awareness Training

- Pre-Competent Person Training

- Requirements of The Electricity, Safety, Quality and Continuity Regulations (ESQCR) 2002

- Substation Appreciation

- CDM 2015 Awareness & National Grid Supplier Requirements (SR/163) Overview Training

- Utility & Construction Training Courses

- BESC AME Overhead Lines

- BESC AME Substation

- EUSR Category 1 - Locate Utility Services & HSG47 Radio Detection (CAT & Genny)

- EUSR Category 2 - Implement Safe (Digging) Excavating Practices

- EUSR Category 3, 4 & 5 - Install, Inspect & Remove Timber, Steel and Proprietary Shoring Systems

- EUSR Category 3, 4 & 5 Refresher - Install, Inspect & Remove Timber, Steel and Proprietary Shoring Systems

- EUSR Approved Abrasive Wheels - Mounting and Practical Use of Equipment

- EUSR Approved Manual Handling

- EUSR Endorsed Butt Fusion Welding

- EUSR Endorsed Electrofusion Welding

- EUSR HSG47 - Avoiding Dangers Underground Services - HV Substations

- EUSR Safe Control of Mains Connection (SCMC) Water Course

- EUSR Endorsed Gas Detection and Personal Gas Monitor Training

- EUSR Endorsed Fire Warden

- EUSR Approved Asbestos Awareness

- EUSR Approved Control of Substances Hazardous to Health (COSHH) Awareness

- EUSR Endorsed Cable Winch - Trailer 3T Capstan Winch

- EUSR Endorsed Cable Winch and Cable Pulling

- EUSR Endorsed Chlorination, De-Chlorination, Flushing & Sampling

- EUSR Endorsed Excavation Management

- EUSR Endorsed Hand Arm Vibration Syndrome (HAVS) Awareness

- EUSR Endorsed Working at Height and Harness Awareness

- Overhead Line Appreciation

- Qualitative Face Fit Testing

- Quantitative Face Fit Testing

- Electrical Training Courses

- City & Guilds 2377-77 In-service Inspection and Testing of Electrical Equipment (PAT Testing)

- City & Guilds 2377-77 In-service Inspection and Testing of Electrical Equipment 3 Day course (PAT Testing)

- City & Guilds 2382-22 18th Edition Full Course (3 days)

- City & Guilds 2382-22 18th Edition BS7671:2018+A2:2022 (1 Day Update including Exam)

- City & Guilds 18th Edition Exam Only

- Thames Water Passport

- Safe Control of Operations (SCO) Gas Training Courses

- EUSR SCO (Safe Control of Operations) Modules 1, 2 & 5: Core, Permit to Work and Form of Authority (Was previously SCO 1&2)

- EUSR SCO (Safe Control of Operations) Modules 1 & 2: Core & Permit to Work (Was previously SCO1)

- EUSR SCO (Safe Control of Operations) Module 3: Non-Routine Operations (NRO) (Was previously SCO4)

- EUSR SCO (Safe Control of Operations) Module 4: Routine Operations (RO) (Was previously SCO5)

- EUSR SCO (Safe Control of Operations) Modules 1, 2 & 5: SCO Core, Permit To Work and Form Of Authority (Previously known as SCO 1&2) Renewal

- EUSR SCO (Safe Control of Operations) Modules 1, 2, 4 & 5: SCO Core, Permit To Work, Routine Operations and Form Of Authority Renewal

- EUSR SCO (Safe Control of Operations) Modules 1, 2, 3, 4 & 5: SCO Core, Permit To Work, Non Routine Operations, Routine Operations and Form Of Authority (Previously known as SCO 1&2, 4 and 5) Renewal

- EUSR SCO (Safe Control of Operations) Module 5: Form of Authority (Was previously part of SCO1&2)

- EUSR SCO (Safe Control of Operations) Module 3: Non-Routine Operations (NRO) (Was previously SCO4) Renewal

- EUSR SCO (Safe Control of Operations) Module 4: Routine Operations (RO) (Was previously SCO5) Renewal

- Network Construction Operations (NCO) Gas / Water Training Courses

- CABWI Level 1 Certificate in Network Construction Operations - NCO1 Water Assistant

- CABWI Level 2 Certificate in Network Construction Operations - NCO2 Water Service Layer

- CABWI Level 2 Certificate in Network Construction Operations - NCO2 Water Main Layer

- CABWI Level 2 Certificate in Network Construction Operations - NCO2 Water Conversion Main and Service Layer

- City & Guilds Level 1 Certificate in Network Construction Operations - NCO1 GAS Assistant

- City & Guilds Level 2 Diploma in Network Construction Operations - NCO2 GAS Service Layer

- City & Guilds Level 2 Diploma in Network Construction Operations - NCO2 GAS Main Layer

- City & Guilds Level 2 Diploma in Network Construction Operations - NCO2 GAS Conversion Main and Service Layer

- EUSR NCO Water Registration

- EUSR NCO Water re-registration

- EUSR NCO Gas Registration

- EUSR NCO Gas re-registration

- National Grid Training Courses

- NG NSI9 Testing High Voltage Equipment

- NG Competent Person Overhead Lines (OHL) CPA LAC ONLY Non-Application of Drain Earths e.g., Civil Works

- NG Competent Person Overhead Lines (OHL) CPB LAC & PFW Non-Application of Drain Earths e.g., Fountain Forestry

- NG Competent Person Overhead Lines (OHL) CPC LAC & PFW Application of Drain Earths (No Access onto Conductors) e.g., Tower Painters who Earth

- NG Competent Person Overhead Lines (OHL) CPD LAC & PFW Application of Drain Earths (Work on Conductors)

- NG Competent Person Substations NSI6 and NSI8 Full

- NG NSI2 Limited Renewal

- NG NSI2 Limited inc Practical Application of Drain Earths

- NG Person Overhead Lines (OHL)

- NG Person Overhead Lines Online Renewal

- NG Person Substations

- NG Person Substations Online Renewal

- NG Restoration of Motive Power (ROMP)

- Streetworks / NRSWA Training Courses

- NRSWA Signing Lighting and Guarding (Operatives)

- NRSWA Signing, Lighting and Guarding (Supervisor)

- NRSWA Signing Lighting and Guarding Reassessment

- NRSWA Operatives Reassessment Course

- NRSWA Supervisors Reassessment Course

- NRSWA Location and Avoidance of Underground Apparatus (LA Old Unit 1)

- NRSWA Location and Avoidance of Underground Apparatus (LA) Reassessment

- CITB Accredited Training Courses

- About us

- Policies

- News & Articles

- Contact

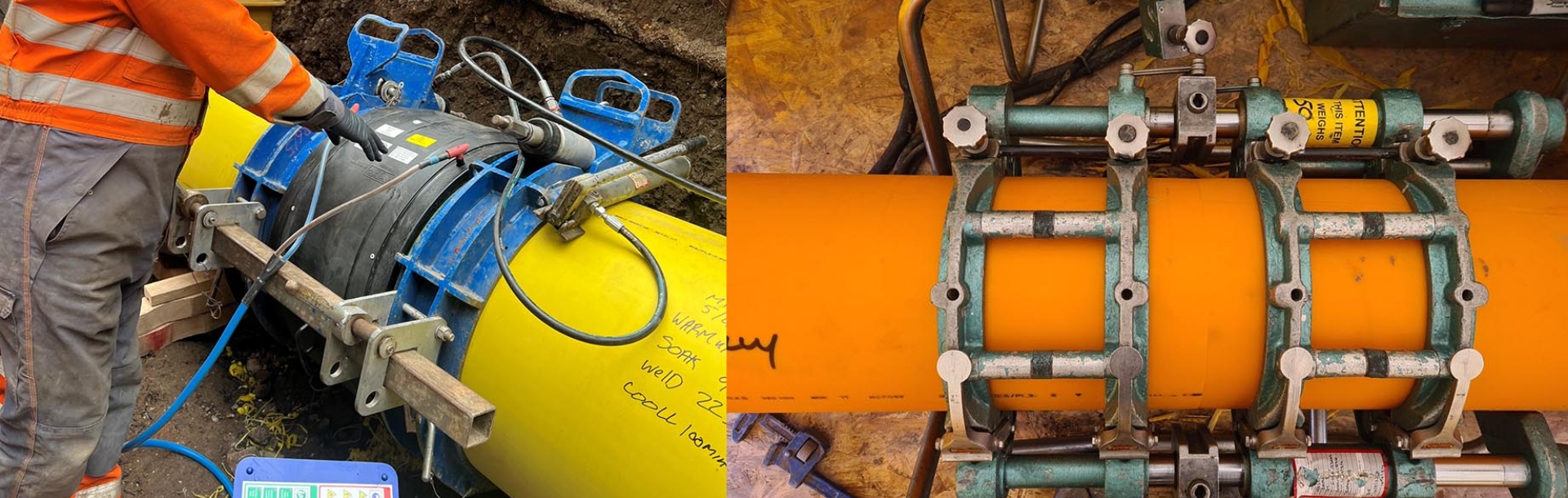

How Do Butt Fusion and Electrofusion Compare? Pros, Cons, and FAQs

PE pipe, or polyethylene pipe is used in water, wastewater and gas distribution networks it is often the material of choice because it's lightweight, durable, flexible, cheap, reduced maintenance and ease of installation as examples.

PE pipe is available in a variety of pipe diameters and thicknesses, and when it arrives on site it tends to arrive in 6m, 12m or 18m straight lengths or on a coil with lengths 50m or 100m typically, however 200m coils are also available some pipe diameters.

This PE pipe then needs to be welded together to form the pipeline and there's two main ways of doing this, butt fusion or electrofusion.

The training requirements for both methods are of similar time scale, usually one to two days depending on the experience of the operative, with the skill set for butt fusion a little more intense.

Where are Butt Fusion and Electrofusion Welding techniques used?

- Gas Distribution

- Clean Water Distribution

- Sewers and Drainage

- Land Irrigation

- Ducting Systems

- Industrial Wastewater

- Radiant floor heating

What Is Butt Fusion Welding for PE Pipes?

With Butt fusion the ends of each length of pipe are heated to start to melt the PE, then pushed together so that as they cool, they form a permanent bond together. This type of technique is still the most popular for welding PE pipe.

In Butt Fusion can the pipes be of different wall thickness?

No, must have same wall thickness and SDR (Standard Dimension Ratio) type.

What size pipe is Butt fusion applicable to?

50mm to 2000mm

What are the typical Failures of Butt fusion?

- Inadequate or Incomplete fusion

- Contamination

- Misalignment / Lack of Parallelism

Advantages of Butt Fusion Welding

- Consistent quality

- Cost effectiveness, suitable for large scale pipeline projects

- Versatility

- Strength – the welded joint is as strong as the pipe itself

- Generally quicker than the electrofusion per joint.

Disadvantages of Butt Fusion Welding

- Equipment: Specialised equipment

- Joints: Requires more construction space on site

- Pipe: Must be of the same material, diameter, and SDR

- Contamination: Contaminated scraped areas of pipe, dirt, grease can impact on the weld quality.

- Weather: Extreme weather (i.e. when too hot or cold outside) will require adjustments and can impact on the weld quality.

- Operator: Following of the correct procedures and accurate control of the weld parameters is crucial. Failure to observe cooling times can compromise the weld.

- Installation Time: Longer

What Is Electrofusion Welding for PE Pipes?

Electrofusion uses a specially designed fitting (socket or collar) in which the two ends of the pipe sit into, an electric current is passed through the collar which melts the outside of the pipe and forms a bond. The collar then stays on the pipe and forms part of the pipeline.

In Electrofusion can the pipes be of different wall thickness?

Yes, different wall thicknesses can be accommodated as the electrofusion joint method uses a socket or collar that fits over the pipes to be jointed, and when an electric current is passed through the socket or collar the pipe wall melts attaching the socket or collar to the pipe

What size pipe is Electrofusion applicable to?

16mm to 710mm

What are the typical Failures of Electrofusion?

- Inadequate or no scraping of pipe

- Contamination

- Misalignment

Advantages of Electrofusion Welding

- Electrofusion jointing can be used on water, gas, sewerage and other industrial PE pipe systems and has the advantage of being able to join smaller pipes, from 16mm up to 710mm.

- The plant requirement for electrofusion is less than for butt fusion.

- Different thicknesses of pipes can be jointed together

Disadvantages of Electrofusion Welding

- Equipment: Specialised equipment and a reliance on a power source.

- Fittings: Fitting cost is deemed high

- Joints: Requires less construction space on site

- Contamination: Contaminated scraped areas of pipe can impact on the weld quality.

- Weather: Extreme weather (i.e. when too hot or cold outside) will require adjustments and can impact on the weld quality.

- Operator: Following of the correct procedures and accurate control of the weld parameters is crucial.

- Installation Time: Shorter

| Feature | Butt Fusion | Electrofusion |

|---|---|---|

| Pipe Sizes | 50mm – 2000mm | 16mm – 710mm |

| Joint Strength | Equal to the pipe | High, includes a fitting |

| Equipment | Large, specialised fusion machine | Compact equipment, fittings required |

| Space Requirements | More site space needed | Works in confined areas |

| Pipes Must Match | Yes – same diameter and SDR | No – handles different wall thickness |

| Fitting Cost | No additional fitting cost | Fittings can be costly |

| Use Case | New large-scale pipelines | Repairs, tight access installations |

Frequently Asked Questions

Can you use butt fusion and electrofusion on the same project?

Yes, many projects use both methods depending on the location and pipe size. Butt fusion for open areas; electrofusion for complex or tight spaces.

Is electrofusion or butt fusion stronger?

Both methods create very strong joints, but butt fusion generally produces a weld as strong as the pipe itself, whereas electrofusion strength also depends on fitting quality.

Which is faster to install?

Per joint, butt fusion is generally faster, but electrofusion may be quicker in complex or constrained environments due to easier setup.

Conclusion

In conclusion both Butt Fusion and Electrofusion offer us reliable solutions for joining PE pipes, each have their own advantages and disadvantages (we have only touched on a few). It’s important that when designing your projects designers take these into account and have the knowledge to ensure a suitable design can then be built.

In general, we tend to see that large infrastructure projects favour Butt Fusion and smaller installations, repairs and areas where space is restricted favour Electrofusion, but each project is different.

Why choose Pragmatic Consulting for your Butt and Electrofusion Welding training?

At Pragmatic Consulting, we offer comprehensive training and certification in both butt fusion and electrofusion welding. Our experienced trainers and assessors work across water and gas utilities to ensure you're fully compliant with industry standards, client expectations, and auditing requirements.

Explore Our Courses:

Let us help your team develop the skills and confidence needed for high-quality, compliant pipe installations.

Read more about Butt Fusion Welding in our blog 'An Introduction to Butt Fusion Welding'.

Registered Office:

Unit 78, Avenue Q

Stoneleigh Park

Kenilworth

Warwickshire

CV8 2LG

Registered company number: 08612308

© 2014 - 2025 Pragmatic Consulting Ltd. All rights reserved.

Home | Privacy Policy | Cookies | Site map | Admin